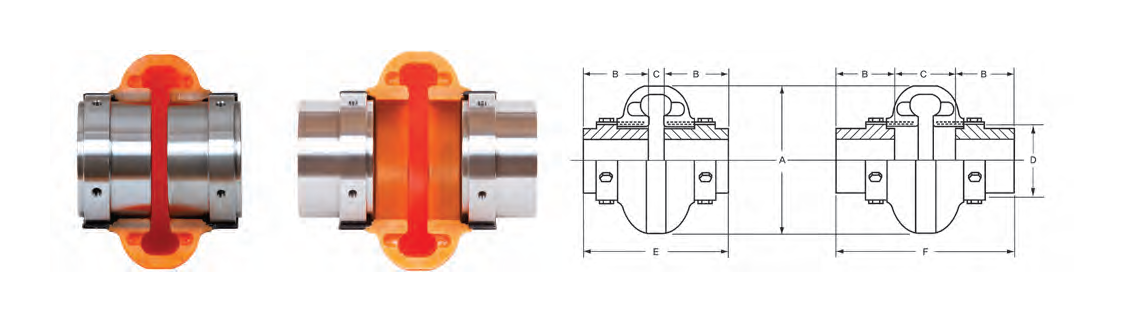

Dynamic® Tyre Couplings

TransDrive Dynamic® Tyre Couplings are specifically engineered to absorb shock, vibration, and torsional movement – offering reliable protection against twirl, twist, impact, and abrasion. Its maintenance-friendly design requires no oil or grease, and replacement of the tyre element can be performed quickly and easily without the need to disconnect motors or adjacent components, significantly reducing downtime.

Versatile in its application, the coupling accommodates dissimilar shaft connections using the same hub, providing flexibility across a wide range of equipment setups. Constructed from high-performance polyurethane, the tyre element delivers outstanding resistance to water, chemicals, and harsh environmental conditions – ensuring long-term durability and consistent performance.

With its combination of strength, simplicity, and adaptability, the TransDrive Dynamic Tyre Coupling is an ideal solution for industrial power transmission systems where efficiency, reliability, and easy of maintenance are essential.

Features & Benefits

- Facility protection for twirl and twist, impact and abrasion

- Very simple replacement and maintenance without oil and grease

- Very simple replacement without the separation of motor or connector on the related line due to its simple structure

- Possible for the dissimilar connection and assembling with same hub

- Polyurethane based for having good water resistance, chemical resistance

- Highest flexible elasticity on run

- Less noise

Service And Safety Factors

| General Application | Service Factor | Industry Application | Service Factor |

|---|---|---|---|

| Agitator | 1.5 | Aggregate Processing Cement | 2.0 – 3.0 |

| Blower | 1.0 – 1.5 | Brewery and Distilling | 1.0 – 2.0 |

| Compressor | 1.0 – 2.0 | Food Industry | 1.0 – 2.0 |

| Conveyor | 1.25 – 1.5 | Lumber Industry | 1.5 – 2.5 |

| Cranes and Hoists | 2.0 – 2.5 | Power Industry | 1.0 – 2.5 |

| Elevators | 1.0 – 2.0 | Pulp and Paper-Mills | 1.0 – 3.5 |

| Fans | 1.0 – 2.0 | Rubber Industry | 1.0 – 3.0 |

| Generators | 1.0 – 2.5 | Steel Industry | 2.0 – 4.5 |

| Pumps | 1.0 – 1.5 | Textile | 1.0 – 2.0 |

| Running Status | Service Factor |

|---|---|

| 1. For being continuous and light load weight | 1.0 |

| 2. for being the various change of the Rotary power | 1.5 |

| 3. for being various and frequent variant on the turning force | 2.0 |

| 4. For being the variation of the rotary power accompanying impact | 2.5 |

| 5. For being high-impact load-weight accompanying slight retro-rotation | 3.0 |

| 6. for being frequent retro-rotation accompanying high-impact | Consult |

Product Specifications

| Dynamic Coupling No. | Torque (kgf.m) | max Bore (mm) | Max. rpm | Power Rating (kW/rpm) | Dimensions (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A Outer Diameter | B Hub Length | C | D Hub Diameter | Total Length | |||||||

| Min. Shaft Spacing | Max. Shaft Spacing | E In | F Out | ||||||||

| D-2 | 2.20 | 28 | 7500 | 0.0023 | 89 | 24 | 35 | 47 | 47 | 83 | 95 |

| D-3 | 4.20 | 34 | 7500 | 0.0043 | 102 | 32 | 9 | 47 | 59 | 83 | 111 |

| D-4 | 6.40 | 42 | 7500 | 0.0066 | 116 | 37 | 9 | 47 | 66 | 83 | 121 |

| D-5 | 11.00 | 48 | 7500 | 0.0110 | 137 | 45 | 10 | 52 | 80 | 100 | 142 |

| D-10 | 16.70 | 55 | 7500 | 0.0170 | 162 | 45 | 11 | 53 | 93 | 101 | 143 |

| D-20 | 26.70 | 65 | 6600 | 0.0270 | 184 | 50 | 15 | 63 | 114 | 115 | 163 |

| D-30 | 42.10 | 75 | 5800 | 0.0430 | 210 | 56 | 12 | 68 | 138 | 124 | 180 |

| D-40 | 63.40 | 85 | 5000 | 0.0660 | 241 | 61 | 12 | 74 | 468 | 134 | 196 |

| D-50 | 88.20 | 90 | 4200 | 0.0900 | 249 | 69 | 12 | 86 | 207 | 150 | 224 |

| D-60 | 144.00 | 105 | 3800 | 0.1480 | 318 | 80 | 11 | 99 | 222 | 171 | 259 |

| D-70 | 254.00 | 120 | 3600 | 0.2620 | 356 | 85 | 18 | 109 | 235 | 189 | 281 |

| D-80 | 455.00 | 155 | 2000 | 0.4670 | 406 | 114 | 17 | 149 | 286 | 245 | 377 |

| D-100* | 980.00 | 171 | 1900 | 1.000 | 533 | 140 | 44 | 95 | 359 | 324 | 375 |

| D-120* | 1961 | 190 | 1800 | 2.000 | 635 | 152 | 57 | 124 | 448 | 362 | 429 |