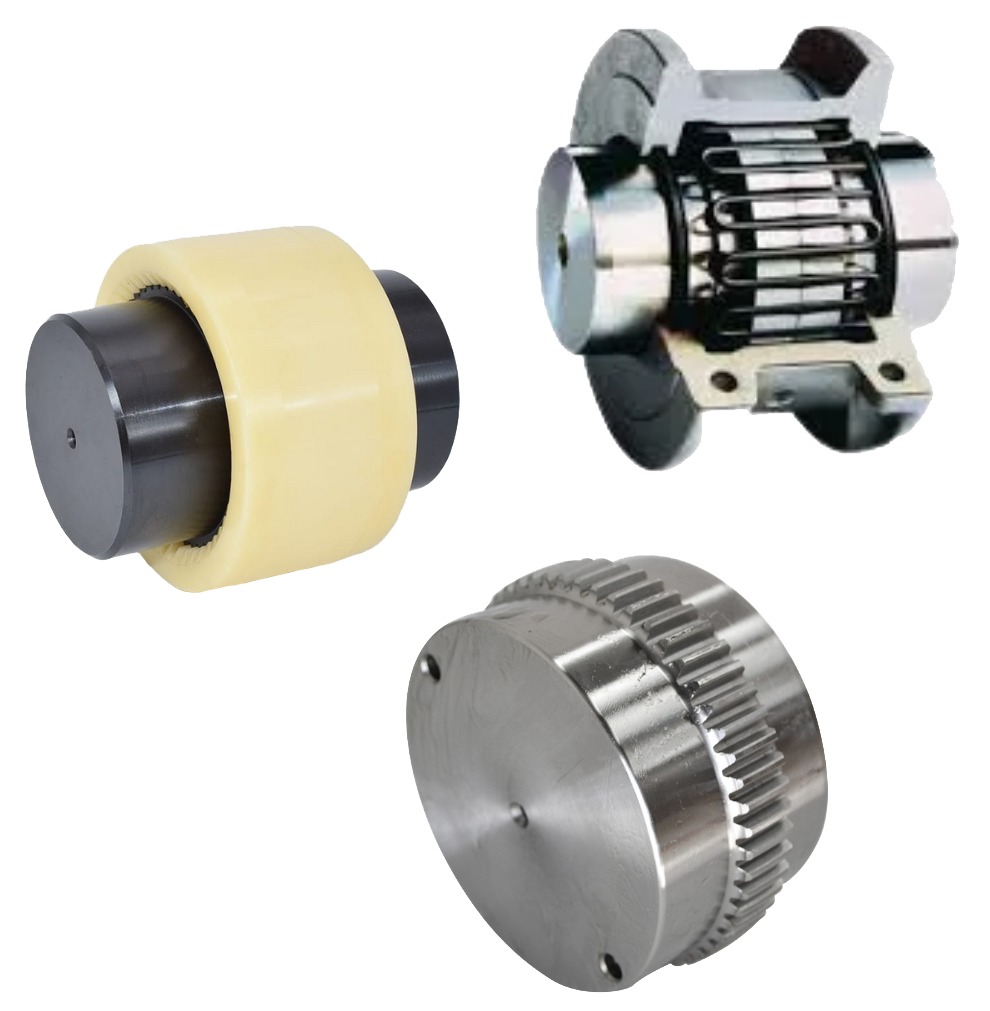

Gear & Grid Coupling Selection

Selection of Method Size

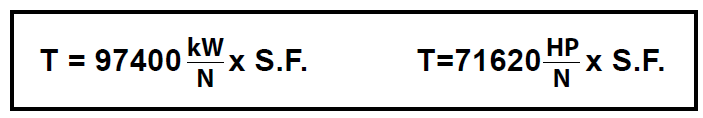

By using the following formula, obtain Design Torque required.

T = Design torque (kg cm) kW = Power (kilo Watts)

HP = Horse Power

N = Working revolution (rpm)

SF = Recommended service factor

Select the size with the same or with the greater value at the Basic Torque column. Refer to the maximum shaft diameters of the size selected and then compare the shaft diameters of the application with the maximum bore diameter of the size selected. If the coupling bore is not suitable, select the larger size coupling.

Special requirements

- On calculating the torque required, use the lowest operating speed (N) of the application.

- If there are reverse motions repeated or frequent irregular kind changes, take service factor twice.

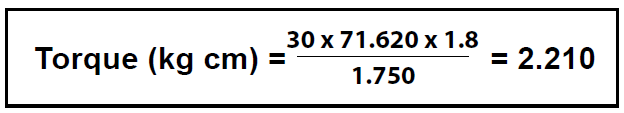

Example

When you select a coupling to connects 30HP, 1, 1750rm motor and rotary type pump. Motor shaft diameter is 48mm and pump’s 52mm.

- Service factor of pump is 1.8

- Normal transmitting power is 30HP

The coupling size 1040 accepts the calculated torque 2210 and then compare the application shaft diameter sizes(52mm) to the maximum bore of the selected coupling size 1040(43mm).

You will select the coupling size 1060 accepting up to 55mm shaft diameter. The size also accepts the application motor speed 1750 rpm. Either H (Horizontal split aluminium) or V (Vertical split steel) cover is available. Finally, the coupling size 1060 is selected.