Chain Coupling

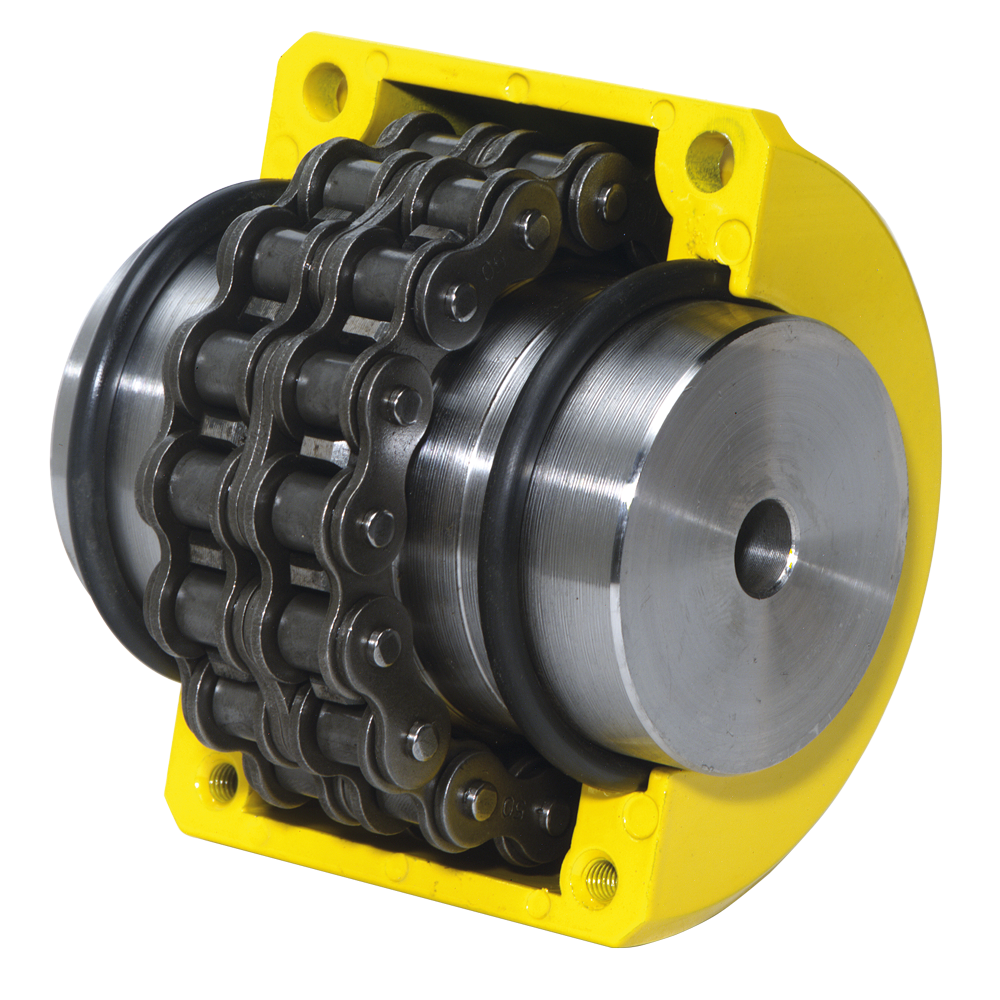

TransDrive Chain Couplings are constructed using two precision-machined sprockets and a high-quality double-strand roller chain, forming a compact yet powerful coupling solution. Their simple design provides excellent flexibility and a higher torque transmission capacity compared to other couplings of similar size.

These couplings are ideal for applications requiring easy assembly and disassembly, as they allow for quick connection and removal without disturbing surrounding equipment. When used with a protective housing, TransDrive chain couplings offer enhanced safety by containing the moving parts, while also extending service life by shielding the components from dust and debris.

Robust, efficient, and easy to maintain, TransDrive Chain Couplings are a reliable choice for a wide range of industrial power transmission applications.

We supply couplings that are tested for ISO standard.

Components

Straight Bore Sprockets & Duplex Roller Chains

The coupling includes a pair of sprockets, one for each shaft being connected. Chain couplings also include Duplex Roller Chains, which are used to connect the two sprockets.

| Part No. | Max RPM | |

|---|---|---|

| Without Cover | With Cover | |

| CC4012 | 875 | 5000 |

| CC4016 | ||

| CC5016 | 800 | 4000 |

| CC5018 | ||

| CC6018 | 675 | 3000 |

| CC6022 | ||

| CC8018 | 500 | 2000 |

| CC8022 | ||

| CC10020 | 450 | 1800 |

| CC12022 | ||

chain Coupling Cover

Made of durable materials like metal or high-strength plastics to withstand the operating conditions of the machinery. They are designed to be easily removable for maintenance and inspection purposes while providing effective protection during normal operation. The cover will also commonly include, connecting pins and a locking arrangement.

| Part No. | For RPM Exceeding |

|---|---|

| CC4012-COV | 875 |

| CC4016-COV | |

| CC5016-COV | 800 |

| CC5018-COV | |

| CC6018-COV | 675 |

| CC6022-COV | |

| CC8018-COV | 500 |

| CC8022-COV | |

| CC10020-COV | 450 |

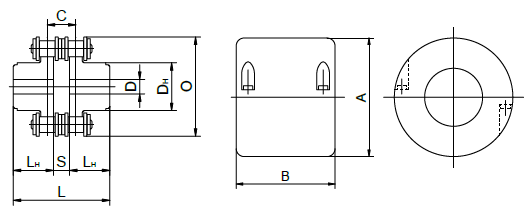

Product Specifications

| Chain Coupling Number | Chain Pitch | Coupling | Casting | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Drill hole | Shaft diam. | O | L | DH | LH | S | C | Approx. weight (kg/m) | A | B | Approx. weight (kg/m) | |||

| Min. | Max. | |||||||||||||

| 3012 | 9.525 | 12 | 13.5 | 16 | 45 | 65 | 27.2 | 29.5 | 6 | 10.1 | 0.31 | 69 | 63 | 0.22 |

| 4012 | 12.70 | 12 | 14 | 22 | 62 | 79.4 | 36 | 36 | 7.4 | 14.4 | 0.73 | 77 | 72 | 0.30 |

| 4014 | 12 | 14 | 28 | 69 | 79.4 | 45 | 36 | 1.12 | 84 | 75 | 0.31 | |||

| 4016 | 13.5 | 16 | 32 | 77 | 87.4 | 51.5 | 40 | 1.50 | 92 | 72 | 0.35 | |||

| 5014 | 15.875 | 14.5 | 17 | 35 | 86 | 99.7 | 56 | 45 | 9.7 | 18.1 | 2.15 | 101 | 85 | 0.47 |

| 5016 | 14.5 | 18 | 40 | 96 | 99.7 | 64 | 45 | 2.75 | 110 | 87 | 0.50 | |||

| 5018 | 16 | 18 | 45 | 106 | 99.7 | 73.5 | 45 | 3.60 | 122 | 85 | 0.60 | |||

| 6018 | 19.05 | 20 | 22 | 56 | 127 | 123.5 | 89.5 | 56 | 11.5 | 22.8 | 6.55 | 147 | 105 | 1.2 |

| 6020 | 20 | 24 | 60 | 139 | 123.5 | 102.5 | 56 | 8.38 | 158 | 105 | 1.2 | |||

| 6022 | 20 | 24 | 71 | 151 | 123.5 | 115 | 56 | 10.4 | 168 | 117 | 1.2 | |||

| 8018 | 20.40 | 20 | 32 | 80 | 169 | 141.2 | 115 | 63 | 15.2 | 29.3 | 13.2 | 190 | 129 | 1.9 |

| 8020 | 20 | 36 | 90 | 185 | 145.2 | 125 | 65 | 16.2 | 210 | 137 | 2.5 | |||

| 8022 | 20 | 40 | 100 | 202 | 157.2 | 142 | 71 | 21.8 | 226 | 137 | 2.7 | |||

| 10020 | 31.75 | 25 | 45 | 110 | 233 | 178.8 | 162 | 80 | 18.8 | 35.8 | 32.4 | 281 | 153 | 4.1 |

| 12018 | 38.10 | 35 | 50 | 125 | 256 | 202.7 | 173 | 90 | 22.7 | 45.4 | 43.2 | 307 | 181 | 5.2 |

| 12022 | 35 | 56 | 140 | 304 | 222.7 | 213 | 100 | 69.1 | 357 | 181 | 6.7 | |||

Power Transmission Capacity

| No. | Max. Shaft diam. (mm) | Allowable Transmission Torque at 50rpm or less (kgf.m) | Coupling Speed (rpm) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 5 | 10 | 25 | 50 | 100 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1200 | 1500 | |||

| CC3012 | 16 | 10.2 | 0.01 | 0.05 | 0.11 | 0.26 | 0.52 | 0.79 | 1.21 | 1.58 | 1.89 | 2.26 | 2.58 | 3.19 | 3.88 | 4.41 | 5.35 |

| CC4012 | 22 | 22.2 | 0.02 | 0.11 | 0.22 | 0.58 | 1.15 | 1.73 | 2.63 | 3.46 | 4.15 | 4.96 | 5.67 | 7.01 | 8.53 | 9.68 | 11.6 |

| CC4014 | 28 | 30.2 | 0.03 | 0.16 | 0.32 | 0.79 | 1.58 | 2.36 | 3.59 | 4.72 | 5.66 | 6.77 | 7.72 | 9.56 | 11.6 | 13.2 | 15.8 |

| CC4016 | 32 | 39.4 | 0.04 | 0.21 | 0.41 | 1.03 | 2.06 | 3.09 | 4.69 | 6.17 | 7.41 | 8.85 | 10.1 | 12.5 | 15.3 | 17.3 | 21.0 |

| CC5014 | 35 | 57.4 | 0.06 | 0.30 | 0.60 | 1.50 | 3.00 | 4.48 | 6.80 | 8.95 | 10.70 | 12.80 | 14.7 | 18.1 | 22.1 | 25.1 | 30.0 |

| CC5016 | 40 | 75.0 | 0.08 | 0.39 | 0.78 | 1.95 | 3.91 | 5.86 | 8.92 | 11.7 | 14.1 | 16.8 | 19.2 | 23.8 | 28.9 | 32.9 | 39.9 |

| CC5018 | 45 | 95.0 | 0.10 | 0.50 | 0.99 | 2.48 | 4.95 | 7.43 | 11.3 | 14.9 | 17.8 | 21.3 | 24.4 | 30.1 | 36.6 | 41.6 | 50.5 |

| CC6018 | 56 | 179 | 0.18 | 0.93 | 1.87 | 4.67 | 9.33 | 14.0 | 21.3 | 28.0 | 33.6 | 40.1 | 45.9 | 56.8 | 69.1 | 78.4 | 95.2 |

| CC6022 | 71 | 242 | 0.25 | 1.25 | 2.51 | 6.31 | 12.5 | 18.8 | 28.6 | 37.7 | 45.3 | 54.1 | 61.9 | 76.5 | 93.1 | 105 | 128 |

| CC8018 | 80 | 396 | 0.41 | 2.07 | 4.14 | 10.3 | 20.7 | 31.0 | 47.2 | 62.1 | 74.5 | 89.0 | 101 | 126 | 153 | 174 | 211 |

| CC8022 | 100 | 570 | 0.59 | 2.96 | 5.93 | 14.8 | 29.6 | 44.5 | 67.2 | 89.0 | 106 | 126 | 153 | 174 | 211 | 246 | 265 |

| CC10020 | 110 | 896 | 0.93 | 4.66 | 9.33 | 23.3 | 46.6 | 70.0 | 106 | 140 | 168 | 200 | 229 | 283 | 345 | 392 | 476 |

| CC12018 | 125 | 1350 | 1.40 | 7.02 | 14.0 | 35.1 | 70.2 | 105 | 160 | 210 | 252 | 302 | 345 | 426 | 519 | 590 | 716 |

| CC12022 | 140 | 1750 | 1.81 | 9.07 | 18.1 | 45.3 | 90.7 | 136 | 206 | 272 | 326 | 390 | 446 | 551 | 671 | 762 | |

| Lubricated Method | A | B | C | ||||||||||||||

| No. | Max. Shaft diam. (mm) | Allowable Transmission Torque at 50rpm or less (kgf.m) | Coupling Speed (rpm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1800 | 2000 | 2500 | 3000 | 3600 | 4000 | 4800 | 5200 | 6000 | |||

| CC3012 | 16 | 10.2 | 6.25 | 6.73 | 8.12 | 9.44 | 11.0 | 12.0 | 14.0 | 14.8 | 16.7 |

| CC4012 | 22 | 22.2 | 13.7 | 14.8 | 17.9 | 20.7 | 24.1 | 26.3 | 30.08 | ||

| CC4014 | 28 | 30.2 | 18.7 | 20.2 | 24.4 | 28.3 | 32.9 | 35.9 | 42.1 | ||

| CC4016 | 32 | 39.4 | 24.4 | 26.3 | 31.9 | 37.0 | 43.0 | 46.9 | 54.9 | ||

| CC5014 | 35 | 57.4 | 35.4 | 38.3 | 46.2 | 53.6 | 62.4 | ||||

| CC5016 | 40 | 75.0 | 46.4 | 50.0 | 60.6 | 70.4 | 81.6 | ||||

| CC5018 | 45 | 95.0 | 58.8 | 63.4 | 76.8 | 89.2 | |||||

| CC6018 | 56 | 179 | 111 | 120 | 145 | ||||||

| CC6022 | 71 | 242 | 149 | 161 | 195 | ||||||

| CC8018 | 80 | 396 | 246 | 265 | |||||||

| CC8022 | 100 | 570 | 352 | 379 | |||||||

| CC10020 | 110 | 896 | 554 | ||||||||

| Lubricated Method | C | ||||||||||

Lubrication

There are three methods to lubricate:

- Greasing Monthly

- Greasing Weekly or fill grease in the attached casing

- Fill grease in the attached casing.

Note

When attaching the casing, use high-quality grease because the grease is pressed to the inside wall of the casing due to centrifugal force, deteriorating lubricating ability of the grease. It is recommended to change the grease periodically to maintain high performance and durability of the coupling.

| Grease change intervals (with casing attached) | ||

|---|---|---|

| Operating Conditions | First Change | 2nd and later changes |

| Operating at 1/2 max speed or higher | 1000 hours | 2000 hours |

| Operating at 1/2 max speed or Lower | 2000 Hours | 4000 Hours |

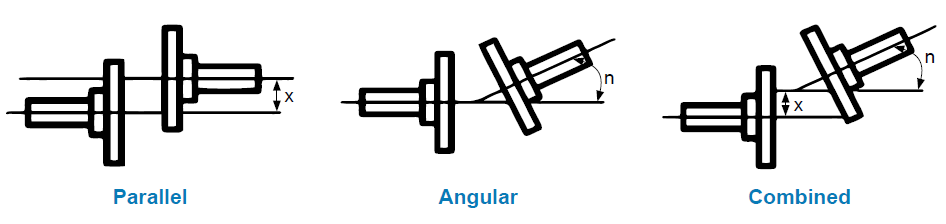

Allowable errors

x = 2% or less of pitch of roller chain used

n = 1 or less

In case of high speed operation, shaft deviation and misalignment must be 1/2 allowable errors.

| Grease change intervals (with casing attached) | |||

|---|---|---|---|

| Chain Coupling No. | Filing Quantity (kg) | Chain Coupling No. | Filing Quantity (kg) |

| CC3012 | 0.08 | 6020 | 0.44 |

| CC4012 | 0.12 | 6022 | 0.48 |

| CC4014 | 0.16 | 8018 | 0.79 |

| CC4016 | 0.17 | 8020 | 0.86 |

| CC5014 | 0.24 | 8022 | 1.00 |

| CC5016 | 0.25 | 10020 | 1.70 |

| CC5018 | 0.26 | 12018 | 3.50 |

| CC6018 | 0.42 | 12022 | 4.50 |