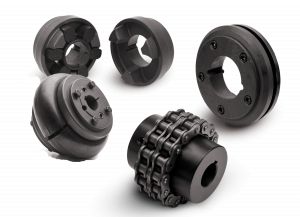

Couplings

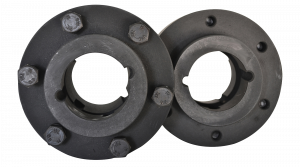

A coupling can be simply defined as “a device that transmits power (torque) from one shaft to another, while allowing some degree of misalignment (angular, parallel or combined) between the two rotating shafts”. Some couplings however, allow for axial (end-float) movement. Also, couplings may be classified as flexible or rigid.

Couplings are used to mechanically connect two shafts to transmit power from one shaft to another. They are also able to compensate for shaft misalignment in a torsionally rigid way.

Misalignment can be angular, parallel or skew. This is particularly important for applications where misalignment could affect the speed and acceleration of the driven shaft. The performance of the coupling depends on how it is installed and maintained.

Depending on the type of coupling required to tolerate a variety of conditions during its service life. Some of these functions could be to:

- Transmit power (torque)

- Permit and accommodate limited amounts of misalignment (angular and/or parallel)

- Allow for ease of assembly, maintenance and dis-assembly

- Allow for some amount of dampening (if required)

- Allow or compensate for end-float/axial movement/thermal expansion

- Retain rigidity between the connecting hubs and the shafts

- Withstand/ compensate for temperature fluctuations/ thermal growth

- Provide protection against overload of the driven machine.

TransDrive supply a range of couplings that complement our chain products.