SE Chain & Belt (Rosta Style) Tensioner Arm

Proven to be a highly effective solution for tensioning both chain and belt drives across a wide range of industrial applications, the TransDrive Rubber Block Series Tensioner is engineered for optimal performance, durability, and minimal maintenance. Its robust design ensures consistent tension, helping to prevent belt slippage, reduce wear, and enhance overall system efficiency.

Whether used in conveyor systems, manufacturing equipment, or automotive engines, the Rubber Block Series delivers reliable, uniform force that supports long-term operational stability and maximises equipment uptime.

Features

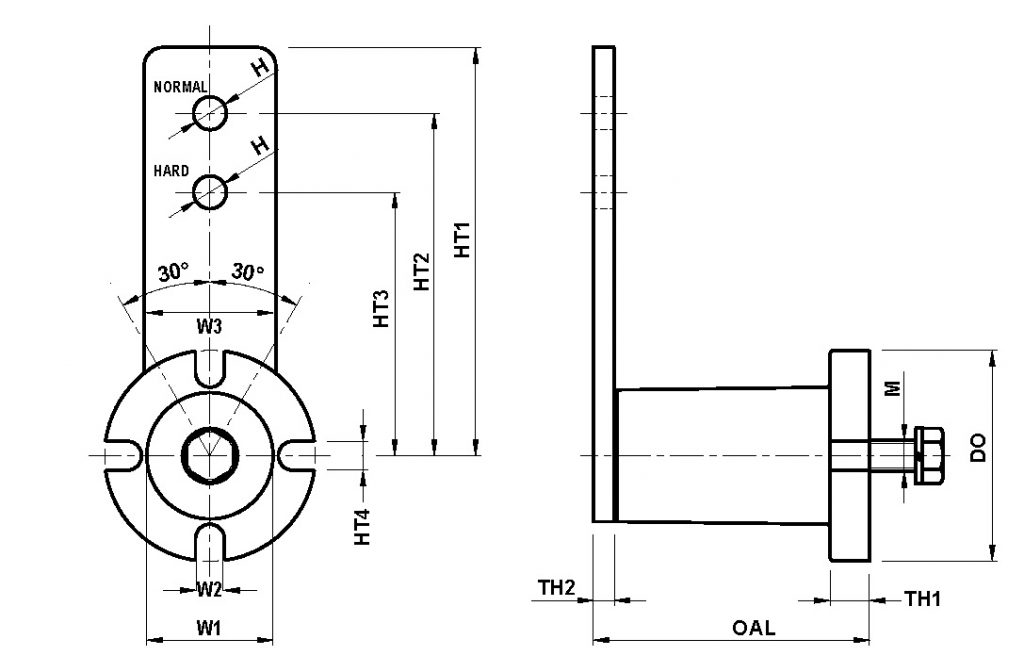

- A one nut mounting system, which allows for 360º rotation.

- Can be pre-tensioned by up to 30º, this means that as the chain or belt stretches, the tensioner automatically takes up the slack as the elastomeric elements automatically adjust the drives tension.

- Chain and Belt life is increased by as much as 30%.

- Elastomeric parts absorb vibrations and shock loading.

- Maintenance Free – no metal on metal parts, lubrication free.

- Impervious to dust and dirt, temperature -40ºC to +80ºC.

- Two holes are provided on the arm, allowing two different levels of force to be generated: “normal” and “hard”. The “hard” setting deploys approximately 25% more force.

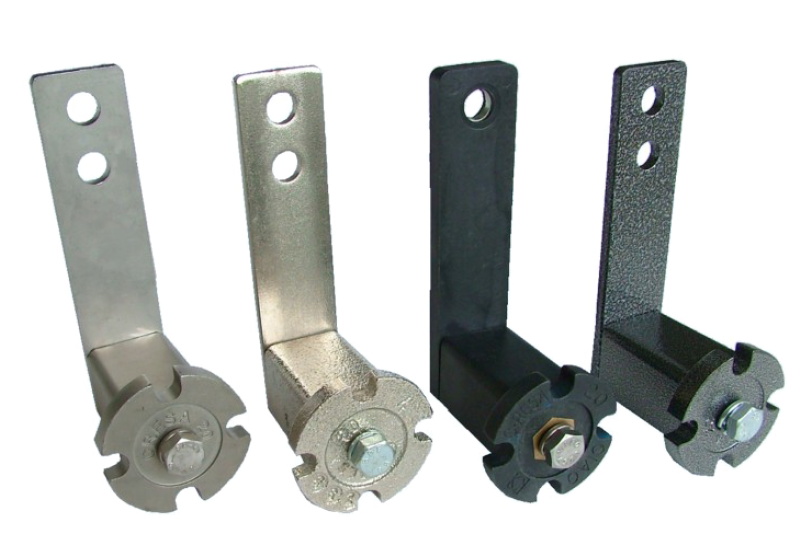

Materials

- Stainless Steel

- Galvanized

- Nickel Plated

- Plastic

Product Specifications

| Type | OD | OAL | M | TH1 | TH2 | HT1 | HT2 | HT3 | HT4 | W1 | W2 | W3 | H | F in n/M 0 – 30º | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SE11 | 35 | 50 | 6 | 5 | 7 | 90 | 80 | 60 | 6 | 20 | 7 | 20 | 8 | 0 – 90 | 0.25 |

| SE15 | 50 | 60 | 8 | 5 | 8 | 110 | 100 | 80 | 8 | 22 | 8 | 30 | 10 | 0 – 140 | 0.45 |

| SE18 | 60 | 75 | 10 | 6 | 10 | 115 | 100 | 80 | 11 | 35 | 9 | 40 | 10 | 0 – 320 | 0.75 |

| SE27 | 80 | 110 | 12 | 8 | 15 | 155 | 135 | 105 | 13 | 45 | 10 | 50 | 12 | 0 – 820 | 1.8 |

| SE38 | 105 | 140 | 16 | 10 | 16 | 200 | 180 | 140 | 15 | 62 | 13 | 65 | 20 | 0 – 1500 | 3.7 |

| SE45 | 115 | 200 | 20 | 12 | 18 | 260 | 225 | 190 | 20 | 78 | 17 | 70 | 20 | 0 – 2500 | 6.5 |

| Type | Angle of Pretension | Mounting Bolt Torque | |||||

|---|---|---|---|---|---|---|---|

| (Force required in psi) | |||||||

| 10º | 20º | 30º | |||||

| Normal | Hard | Normal | Hard | Normal | Hard | ||

| SE11 | 3.4 | 4.5 | 9.0 | 11.9 | 18.0 | 23.9 | 89 |

| SE15 | 5.6 | 7.0 | 14.6 | 18.2 | 30.4 | 37.8 | 221 |

| SE18 | 16.9 | 20.9 | 40.5 | 50.6 | 78.7 | 98.2 | 434 |

| SE27 | 33.8 | 43.8 | 85.4 | 111.1 | 179.8 | 233.8 | 761 |

| SE38 | 65.3 | 81.4 | 164.1 | 205.0 | 337.2 | 421.5 | 1859 |

| SE45 | 112.5 | 140.5 | 292.5 | 365.6 | 584.5 | 730.7 | 3629 |

to absorb vibrations and shock loads, and still have enough arc motion to automatically take up belt or chain

stretch.

| Tensioner Selection | ||

|---|---|---|

| Chain | Belt | Tensioner |

| 25-1 | A | SE11 |

| 35-1-2-3 | A, B | SE15 |

| 35-1-2-3 | B,C | SE18 |

| 40-1-2-3 | ||

| 40-3 | D, E | SE27 |

| 50-1-2-3 | ||

| 60-1-2-3 | ||

| 80-1-2-3 | – | SE38 |

| 80-3 | – | SE45 |

| 100-1-2-3 | ||

| 120-1-2-3 | ||

| 140-1-2 | ||

| 160-1-2 | ||

| 180-1-2 | ||

| 200-1-2 | ||