Jaw Couplings

TransDrive offers a comprehensive range of high-quality Jaw Couplings in various pre-bored and keyed sizes. Available in both pilot bore and taper fit options, these couplings allow for quick and precise final machining. TransDrive stock a wide selection of imperial and metric bushes to suit your application.

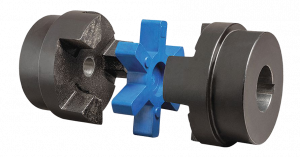

Also known as spider couplings, Jaw Couplings feature a flexible elastomeric insert that transmits torque while compensating for misalignment. The durable rubber elements absorbs shock loads and eliminates metal-to-metal contact, ensuring smooth and quiet operation.

Widely used across multiple industries, TransDrive Jaw Couplings are highly resilient, maintenance-free, and suitable for harsh environments containing oil, dirt, sand, moisture, or grease. Their design accommodates a broad range of bore and keyway combinations, providing reliable performance in light, medium, and heavy-duty applications involving electric motors and internal combustion engines.

TransDrive supply standard, heavy-duty and super-heavy duty spider inserts. Our curved jaw couplings are particularly well-suited for high-torque and hydraulic applications, including hydraulic bell housing drives.