HRC Couplings

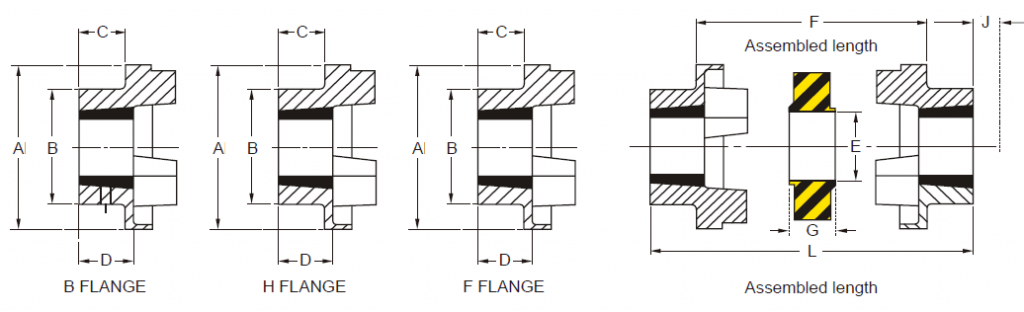

TransDrive HRC Couplings are a trusted and reliable solution for a wide variety of power transmission applications. Each coupling consists of two high-quality cast iron flanges and a rubber element that operates under compression to transmit torque smoothly while absorbing shock and vibration.

The modular design allows for quick installation and straightforward maintenance, making them ideal for reducing downtime in busy industrial environments. TransDrive HRC Couplings are available in a wide selection of configurations, including flexible elements made from Nitrile or polyurethane, and hub options in both pilot bore and taper lock designs – ensuring compatibility with a broad range of shaft sizes and machinery requirements.

Product Specifications

| Size | Bush | Bore | C | D | Bored to Size | Diameter | F | G | L1 | L2 | L3 | J | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bore+ | C | D | ||||||||||||||||

| Max | Min | Max | Min | A | B | C | ||||||||||||

| 70 | 1008 | 25 | 9 | 19.0 | 23.5 | 32 | 8 | 21 | 25 | 69 | 60 | 31 | 27 | 18 | 65 | 66.5 | 68 | 29 |

| 90 | 1108 | 28 | 9 | 18.5 | 23.5 | 38 | 8 | 26 | 30 | 85 | 65 | 32 | 32.5 | 22.5 | 69.5 | 75 | 82.5 | 29 |

| 110 | 1610 | 42 | 11 | 18.5 | 26.5 | 55 | 8 | 37 | 45 | 112 | 100 | 45 | 45 | 29 | 82 | 100.5 | 119 | 38 |

| 130 | 1610 | 42 | 14 | 17.5 | 26.5 | 60 | 36 | 47 | 55 | 130 | 105 | 50 | 54 | 36 | 89 | 117.5 | 145 | 38 |

| 150 | 2012 | 50 | 14 | 23.0 | 33.5 | 65 | 40 | 50 | 60 | 150 | 115 | 62 | 61 | 40 | 107 | 133.5 | 160 | 42 |

| 180 | 2517 | 60 | 16 | 34.0 | 46.5 | 80 | 46 | 58 | 70 | 180 | 125 | 77 | 74 | 49 | 142 | 165.5 | 189 | 48 |

| 230 | 3020 | 75 | 25 | 39.5 | 52.5 | 100 | 52 | 77 | 90 | 225 | 155 | 99 | 85.5 | 59.4 | 142 | 202 | 239.5 | 55 |

| 280 | 3535 | 90 | 35 | 74 | 90.5 | 115 | 62 | 90 | 105 | 275 | 185 | 119 | 107.5 | 74.5 | 142 | 270 | 284.5 | 67 |

Physical Characteristics

| Size | Power Rating Per 100 rev/min | Maximum Speed* (rev/min) | Torque Rating (Nm) | Moment of Inertia MR2 (kgm2) | Torsional Stiffness (Nm/o) | Maximum Misalignment | Mass (kg) | ||

|---|---|---|---|---|---|---|---|---|---|

| Normal | Maximum | Parallel | Axial | ||||||

| 70 | 0.33 | 9100 | 31.5 | 72 | 0.00085 | 10.2 | 0.3 | +0.20 | 1.00 |

| 90 | 0.84 | 7400 | 80 | 180 | 0.00115 | 25.5 | 0.3 | +0.49 | 1.17 |

| 110 | 1.168 | 5630 | 160 | 360 | 0.00400 | 48.0 | 0.3 | +0.61 | 5.00 |

| 130 | 3.30 | 4850 | 315 | 720 | 0.00780 | 84.0 | 0.4 | +0.79 | 5.46 |

| 150 | 6.28 | 4200 | 600 | 1500 | 0.01810 | 176 | 0.4 | +0.92 | 7.11 |

| 180 | 9.95 | 350 | 950 | 2350 | 0.04340 | 240 | 0.4 | +1.09 | 16.60 |

| 230 | 20.9 | 2800 | 2000 | 5000 | 0.12068 | 336 | 0.5 | +1.32 | 26.00 |

| 280 | 33.0 | 230 | 3150 | 7200 | 0.44653 | 960 | 0.5 | +1.70 | 50.00 |

Power Ratings (kW)

| Speed rev/min | Coupling Size | |||||||

|---|---|---|---|---|---|---|---|---|

| 70 | 90 | 110 | 130 | 150 | 180 | 230 | 280 | |

| 100 | 0.33 | 0.84 | 1.68 | 3.30 | 6.28 | 9.95 | 20.9 | 33.0 |

| 200 | 0.66 | 1.68 | 3.35 | 6.6 | 12.6 | 19.9 | 11.9 | 65.0 |

| 400 | 1.32 | 3.35 | 6.70 | 13.2 | 25.1 | 39.8 | 83.8 | 132 |

| 600 | 1.98 | 5.03 | 10.1 | 19.8 | 37.7 | 59.7 | 126 | 198 |

| 720 | 2.37 | 6.03 | 12.1 | 23.8 | 45.2 | 71.6 | 151 | 238 |

| 800 | 2.64 | 6.70 | 13.4 | 26.4 | 50.3 | 79.6 | 168 | 264 |

| 960 | 3.17 | 8.04 | 16.1 | 31.7 | 60.3 | 95.5 | 201 | 317 |

| 1200 | 3.96 | 10.1 | 20.1 | 39.6 | 75.4 | 119 | 251 | 396 |

| 1440 | 4.75 | 12.1 | 24.1 | 47.5 | 90.5 | 143 | 302 | 475 |

| 1600 | 5.28 | 13.4 | 26.8 | 52.8 | 101 | 159 | 335 | 528 |

| 1800 | 5.94 | 15.1 | 30.2 | 59.4 | 113 | 179 | 377 | 594 |

| 2000 | 6.60 | 16.8 | 33.5 | 66.0 | 126 | 199 | 419 | 660 |

| 2200 | 7.26 | 18.4 | 36.9 | 72.6 | 138 | 219 | 461 | 726 |

| 2400 | 7.92 | 20.1 | 40.2 | 79.2 | 151 | 239 | 503 | – |

| 2600 | 8.58 | 21.8 | 43.6 | 85.8 | 163 | 259 | 545 | – |

| 2880 | 9.50 | 24.1 | 48.3 | 95 | 181 | 286 | – | – |

| 3000 | 9.90 | 25.1 | 50.3 | 99 | 188 | 298 | – | – |

| 3600 | 11.90 | 30.1 | 60.3 | 118 | 226 | – | – | – |